top of page

Search

Mastering Spiral Dryer Fabric Manufacturing: Essential Practices and Technical Insights

In the world of Paper Machine Clothing (PMC), spiral dryer fabrics play a critical role in ensuring efficient drying processes, fabric stability, and overall paper production quality. At PMC Centre, we delve into the intricacies of spiral fabric manufacturing to help fabric manufacturers optimize their operations. Drawing from real-world queries and expert responses, this blog post explores key aspects of spiral formation, assembly, and performance influencing factors. Whethe

Snehes Dasgupta

Jan 224 min read

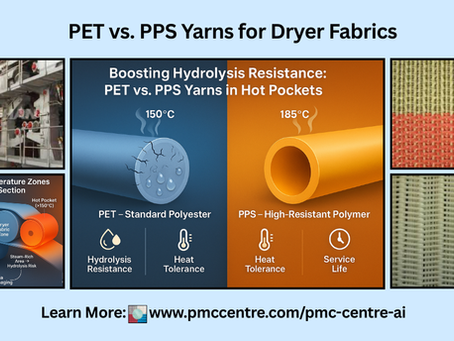

PET vs. PPS Yarns for Dryer Fabrics

In demanding dryer sections, hydrolysis weakens yarn integrity under high heat and humidity, shortening fabric life and raising costs. Hot pockets (>150°C) intensify this risk, requiring materials that balance durability with performance. This article compares PET vs. PPS yarns and key monitoring practices to limit thermal breakdown. 1. PET Yarns: Enhancing Standard Durability: Polyester (PET) yarns offer cost-effective permeability for most dryer applications but degrade

Snehes Dasgupta

Jan 32 min read

Navigating Dryer Fabric Challenges: Key Pain Points and Solutions for Woven and Spiral Designs in Paper Machines

In today's high-speed paper machines processing high-fines and recycled furnishes, the dryer section remains a critical bottleneck for efficiency and profitability. Woven and spiral dryer fabrics each offer unique advantages—such as stability and permeability—but mismatching them to machine positions, heat loads, or contaminants can lead to sheet defects, elevated energy use, and frequent downtime. Drawing from recent industry insights, this post outlines the top pain points

Snehes Dasgupta

Dec 5, 20253 min read

Woven vs. Spiral Dryer Fabrics: Where to Use Which, and Why

In the high-stakes dryer sections of paper machines, selecting and positioning the right fabric—woven or spiral—can significantly enhance drying efficiency, sheet quality, and operational uptime. Woven fabrics excel in controlled contact and surface finish, while spirals prioritize permeability and durability in demanding conditions. This comprehensive guide combines insights from our recent LinkedIn series to help technical teams optimize placements, drawing on proven applic

Snehes Dasgupta

Nov 24, 20253 min read

bottom of page