top of page

Search

All Posts

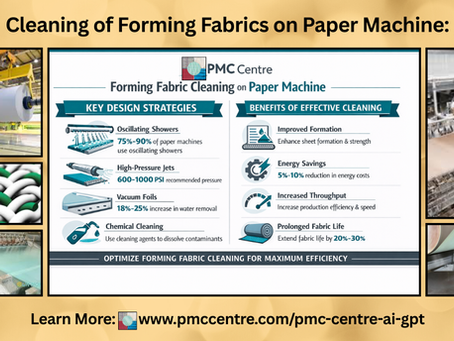

Guide for Cleaning and Conditioning Forming Fabrics for Paper Machines

Maintaining the cleanliness and conditioning of forming fabrics is one of the most critical yet often misunderstood aspects of maximizing runnability and paper quality in modern paper machines. In the high-speed and high-contaminant environment of today’s furnish — particularly with the increased use of recycled fibers — forming fabric performance directly influences drainage efficiency, sheet formation, fiber retention, runnability, and ultimately the economic performance of

Snehes Dasgupta

7 days ago10 min read

Mastering Spiral Dryer Fabric Manufacturing: Essential Practices and Technical Insights

In the world of Paper Machine Clothing (PMC), spiral dryer fabrics play a critical role in ensuring efficient drying processes, fabric stability, and overall paper production quality. At PMC Centre, we delve into the intricacies of spiral fabric manufacturing to help fabric manufacturers optimize their operations. Drawing from real-world queries and expert responses, this blog post explores key aspects of spiral formation, assembly, and performance influencing factors. Whethe

Snehes Dasgupta

Jan 224 min read

Latest Advances in High-Support Forming Fabrics

In the high-stakes world of modern papermaking, where machines run at blistering speeds and every percentage point in efficiency counts, the wet end remains the battleground for optimizing drainage, retention, and sheet quality. As production demands escalate—coupled with relentless pressure to slash energy costs and minimize environmental impact—forming fabrics must evolve beyond traditional designs. A landmark study from Albany International, presented at PaperCon 2011, spo

Snehes Dasgupta

Jan 175 min read

A Practical Guide to Forming Fabric Design for Retention

In the fast-paced world of high-speed paper production, retention isn't just a metric—it's a cornerstone of efficiency. Poor retention results in lost fillers and fines, escalating chemical costs, inconsistent sheet quality, and ultimately, reduced mill profitability. For fabric manufacturers, the challenge lies in designing forming fabrics that enhance retention while maintaining optimal drainage and formation. This guide delves into the critical design elements—caliper, voi

Snehes Dasgupta

Jan 104 min read

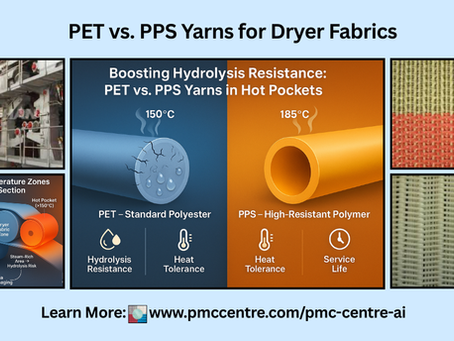

PET vs. PPS Yarns for Dryer Fabrics

In demanding dryer sections, hydrolysis weakens yarn integrity under high heat and humidity, shortening fabric life and raising costs. Hot pockets (>150°C) intensify this risk, requiring materials that balance durability with performance. This article compares PET vs. PPS yarns and key monitoring practices to limit thermal breakdown. 1. PET Yarns: Enhancing Standard Durability: Polyester (PET) yarns offer cost-effective permeability for most dryer applications but degrade

Snehes Dasgupta

Jan 32 min read

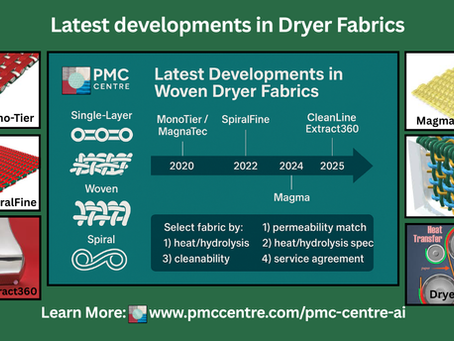

Latest Developments in Dryer Fabrics (2020–2025):

Dryer fabrics have evolved significantly over the past five years, with innovations targeting heat-resistance, cleanability, single-layer performance, and new constructions that improve drying efficiency and runnability on fast machines. These advances reduce energy use, limit seam/marking defects, and extend fabric life — critical for both paper makers and fabric manufacturers. As part of PMC Centre’s weekly series, here is a concise, fact-based overview of the latest develo

Snehes Dasgupta

Dec 26, 20252 min read

Navigating Dryer Fabric Challenges: Key Pain Points and Solutions for Woven and Spiral Designs in Paper Machines

In today's high-speed paper machines processing high-fines and recycled furnishes, the dryer section remains a critical bottleneck for efficiency and profitability. Woven and spiral dryer fabrics each offer unique advantages—such as stability and permeability—but mismatching them to machine positions, heat loads, or contaminants can lead to sheet defects, elevated energy use, and frequent downtime. Drawing from recent industry insights, this post outlines the top pain points

Snehes Dasgupta

Dec 5, 20253 min read

Woven vs. Spiral Dryer Fabrics: Where to Use Which, and Why

In the high-stakes dryer sections of paper machines, selecting and positioning the right fabric—woven or spiral—can significantly enhance drying efficiency, sheet quality, and operational uptime. Woven fabrics excel in controlled contact and surface finish, while spirals prioritize permeability and durability in demanding conditions. This comprehensive guide combines insights from our recent LinkedIn series to help technical teams optimize placements, drawing on proven applic

Snehes Dasgupta

Nov 24, 20253 min read

Excess Water Carry-Over in Forming Fabrics: A Comprehensive Guide for Paper Makers and Fabric Manufacturers

Introduction: In the forming section of paper machines, excess water carry-over represents a pervasive challenge that undermines efficiency, escalates energy consumption, and compromises sheet quality. This phenomenon occurs when forming fabrics retain or transport surplus water into subsequent sections, such as the press and dryer, leading to higher steam demands, reduced machine speeds, and increased operational costs. For paper makers, it manifests as hidden energy drains

Snehes Dasgupta

Nov 13, 20255 min read

Tackling Guiding and Alignment Challenges in Forming Fabrics: A Guide for Paper Makers and Manufacturers

In the fast-paced world of paper production, few issues are as disruptive as forming fabric wandering—where imbalances in tension,...

Snehes Dasgupta

Oct 1, 20254 min read

Seam Failure in Forming Fabrics: Expert Tips for Paper Makers and Forming Fabric Manufacturers

Seam failure in forming fabrics can cause significant disruptions in paper mills, leading to costly downtime and decreased productivity. This blog post will delve into the reasons seam failure occurs and provide actionable insights for both paper makers and forming fabric manufacturers. Understanding the Impact of Seam Failure for Paper Makers Seam failure is a critical issue that can create major problems in a paper production environment. A broken seam can halt a production

Snehes Dasgupta

Sep 27, 20254 min read

Mastering Sheet Formation: A Collaborative Guide for Paper Makers and Forming Fabric Manufacturers

Poor sheet formation —characterized by uneven fiber distribution, mottling, and inconsistent quality—poses a significant challenge in paper production, impacting strength, printability, and operational efficiency. At PMC Centre , we bridge the gap between paper makers and forming fabric manufacturers, combining expert insights to address this pain point holistically. By understanding the interplay of pulp properties, machine configurations, and fabric design, both sides can c

Snehes Dasgupta

Sep 18, 20254 min read

Tackling Uneven Wear in Forming Fabrics: A Guide for Paper Makers and Manufacturers

In the high-stakes world of paper production, uneven wear on Forming Fabrics can spell trouble—from compromised sheet quality to unexpected downtime. At PMC Centre, we specialise in Paper Machine Clothing (PMC) solutions that bridge the gap between paper mills and fabric manufacturers. This blog dives deep into the causes, impacts, and practical fixes for uneven wear, drawing from real-world challenges faced by both Paper Makers and Forming Fabric Manufacturers. Whether you'r

Snehes Dasgupta

Sep 15, 20254 min read

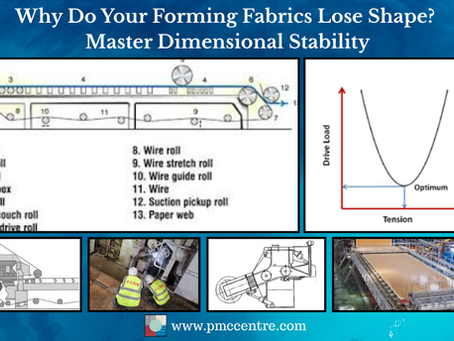

Why Does Your Forming Fabric Lose Shape Too Soon? Mastering Dimensional Stability

Why Does Your Forming Fabric Lose Shape? Mastering Dimensional Stability

Poor dimensional stability in forming fabrics—lengthwise elongation or widthwise shrinkage—causes sheet defects, downtime, and higher costs. This blog explores how paper makers and manufacturers can address this critical issue.

Snehes Dasgupta

Sep 2, 20255 min read

Optimizing Fibre Retention in Forming Fabrics: A Collaborative Guide for Paper Makers and Manufacturer

A detailed look at the texture and weave of a forming fabric Fibre retention is essential in papermaking. It directly impacts the strength, quality, and cost-effectiveness of the final product. When fibre retention drops, results can be serious: weaker sheets, higher production costs, and unnecessary waste. Collaborating effectively between paper makers and forming fabric manufacturers can address these issues. This guide explores the intricacies of fibre retention, the chall

Snehes Dasgupta

Aug 22, 20253 min read

Understanding Beran's Fibre Support Index and Its Impact on Papermaking Efficiency

Dr. Robert Beran, in 1978, developed the Fibre Support Index (FSI) as a two-dimensional mathematical model to quantify a forming fabric's ability to support fibers during the paper sheet formation process. This single numerical value (FSI) allows for objective assessment and comparison of different forming fabric designs based on their resistance to fiber embedment.

Snehes Dasgupta

Aug 13, 20255 min read

Combating Wire Marking in Paper Production

Wire marking—those unwanted impressions left by the forming fabric (or "wire")—can sabotage sheet quality, increase rejects, and inflate costs. While the core issue often stems from the fabric itself, here we’re zeroing in on how Paper Makers, can take charge and keep production top-notch and also what Fabric Manufacturers do to reduce wire marking. How to Combat Wire Marking from Paper Makers End: 1. Uneven Wire Surface or Wear: Worn or uneven wire weaves transfer patte

Snehes Dasgupta

Aug 12, 20252 min read

Managing Edge Curl in Forming Fabrics

Edge curling in forming fabrics poses a notable challenge for both paper makers and fabric manufacturers, especially for Fourdrinier machines. This issue can disrupt both paper quality and manufacturing efficiency, ultimately affecting profitability. To effectively tackle these challenges, it is crucial to understand the root causes of upward edge curl and identify actionable management strategies. Strategies for Paper Makers: Consequences of Upward Edge Curl Upward edge curl

Snehes Dasgupta

Aug 12, 20254 min read

How to Effectively Manage Wire Marking Issues to Enhance Your Paper Quality

Wire marking can be a major setback in paper production, impacting the overall quality of sheets and leading to increased rejects and costs. As paper makers, it’s crucial to take proactive steps to combat these unwanted impressions caused by the forming fabric. By understanding the underlying causes of wire marking and implementing targeted solutions, you can maintain a high standard in your paper products. Let’s delve into how you can take control of this issue and enhance y

Snehes Dasgupta

Aug 3, 20253 min read

How to Solve Common Forming Fabric Issues in Paper Machine Clothing (PMC): Expert Tips from PMC CENTRE

Paper machine clothing (PMC) plays a crucial role in the paper manufacturing process. However, various challenges can arise concerning the forming fabric that can significantly impact production efficiency and quality. This blog post aims to address these common issues and provide expert tips straight from PMC CENTRE. Understanding Common Issues in Forming Fabrics Forming fabrics are essential components of paper machines. They help in shaping and dewatering the paper during

Snehes Dasgupta

Jun 4, 20254 min read

bottom of page