Mastering Sheet Formation: A Collaborative Guide for Paper Makers and Forming Fabric Manufacturers

- Snehes Dasgupta

- Sep 18, 2025

- 4 min read

Poor sheet formation—characterized by uneven fiber distribution, mottling, and inconsistent quality—poses a significant challenge in paper production, impacting strength, printability, and operational efficiency.

At PMC Centre, we bridge the gap between paper makers and forming fabric manufacturers, combining expert insights to address this pain point holistically. By understanding the interplay of pulp properties, machine configurations, and fabric design, both sides can collaborate to achieve smoother, high-quality sheets. Below, we explore key factors from both perspectives, offering actionable strategies to optimize sheet formation. ---

For Paper Makers:

Navigating Pulp and Machine Challenges Paper makers face the daily challenge of transforming pulp into uniform sheets, where formation issues can lead to web breaks, higher rejects, and increased costs. Here’s a breakdown of the critical factors influencing sheet formation, rooted in mill-floor expertise:

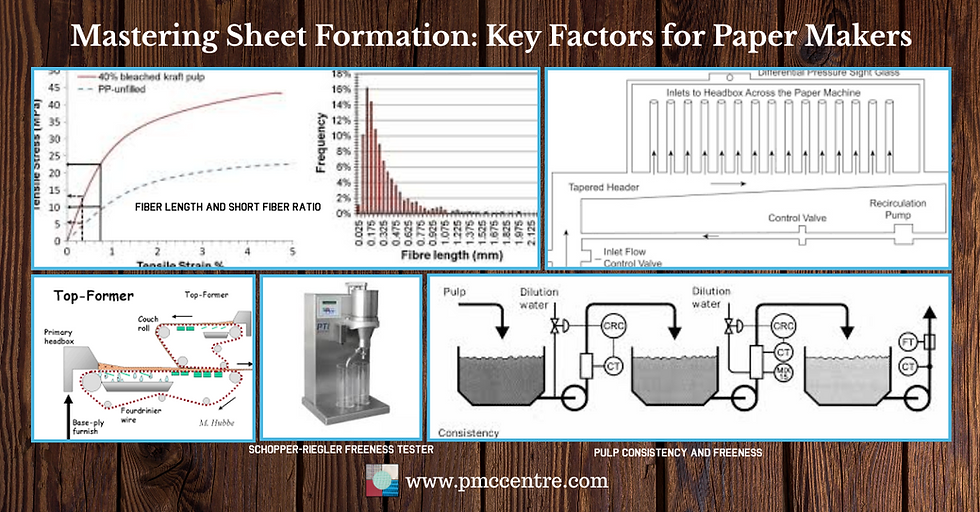

1. Fiber Length and Short Fiber Mix: Long fibers, while strong, often clump at low SR degrees, causing flocculation and uneven sheets. A balanced mix of short fibers enhances interlocking, promoting uniform distribution during dewatering for smoother, more consistent formation.

2. Modern Headbox and Gap Formers: Advanced hydraulic headboxes deliver floc-free stock, enabling high-speed gap formers to “freeze” sheets instantly over short twin-wire paths. This minimizes reflocculation, yielding exceptional formation compared to traditional setups.

3. Degree of SR and Hemicellulose Influence: Higher SR levels (e.g., 20-40° for fine papers) shorten fibers for better dispersion, improving formation but potentially weakening strength. Hemicellulose boosts flexibility and fills voids, enhancing uniformity without over-refining.

4. Filler Percentage Role: Strategic use of fillers (15-30%) smooths sheet hills and voids, enhancing formation and surface quality, provided pulp consistency remains optimal (0.3-1.0%) to avoid flow disruptions.

5. Older Fourdrinier Configurations: In legacy Fourdrinier machines, precise table setups, foil angles, headbox consistency, and fabric tension (4-7 kg/cm) are critical. Misalignments or suboptimal settings disrupt drainage, leading to scattered fiber distribution and poor formation.

Impact: These factors directly influence paper strength, printability, and production efficiency. Poor formation increases breaks, rejects, and waste, driving up costs.

Action for Paper Makers: Optimize pulp preparation, refine headbox settings, and ensure machine configurations align with fabric performance. Collaborate with fabric suppliers to match designs to your specific pulp and equipment needs.

For Forming Fabric Manufacturers:

Designing for Precision and Performance Forming fabric manufacturers hold the key to enabling mills to achieve uniform sheets, especially as machine speeds climb (500-1500 m/min). Your designs must balance fiber/filler retention, minimal wire marking, and controlled dewatering.

Here are the top design considerations for superior formation:

1. High-Speed Machine Demands: At higher speeds, precise retention is critical to prevent fiber and filler loss, while controlled dewatering reduces wire marking. Design fabrics with optimized permeability to harmonize drainage and retention, ensuring excellent sheet properties.

2. Adapting to Fiber Length and Ratios: Understand the mill’s pulp composition—long vs. short fiber percentages. Tailor MD and CD frame lengths to support short fibers for uniformity while managing long fiber flocculation, fostering consistent interlocking and smooth formation.

3. Trend Toward Thinner Fabrics: Modern designs favor thinner fabrics with finer warp/weft diameters to achieve a high Fiber Support Index (FSI > 150). This boosts retention without hindering drainage, minimizing wire marks for uniform, high-quality sheets.

4. Finer SSB Designs for Precision: Sophisticated 20- or 24-shaft SSB (sheet support binding) designs, using warp or weft binders, allow customized surface topography. Each configuration optimizes fiber support and dewatering consistency, delivering mark-free sheets with superior formation.

Impact: These design choices enhance mill performance—better formation, higher retention, fewer defects, and stronger sheets—giving your clients a competitive edge.

Action for Manufacturers: Partner with mills to analyze pulp profiles and machine specs, tailoring fabric designs to specific needs. Leverage advanced SSB weaves and thinner profiles to stay ahead in formation-driven innovation.

Bridging the Gap:

Collaboration is Key Achieving optimal sheet formation requires paper makers and fabric manufacturers to work in sync. Paper makers can fine-tune pulp preparation (e.g., balancing SR and fillers) and machine settings (e.g., headbox flow, tension, foil angles), while manufacturers design fabrics that complement these efforts with high FSI, precise permeability, and advanced SSB structures. This synergy minimizes flocculation, enhances retention, and ensures uniform dewatering, even on high-speed or legacy machines.

Why It Matters: Superior formation translates to stronger, printable sheets, fewer production disruptions, and lower costs—a win for both mills and fabric suppliers.

PMC Centre’s Role: Our unbiased consultancy bridges both perspectives, offering tailored guidance without pushing fabric sales. We help paper makers optimize processes and manufacturers refine designs, fostering collaboration for measurable results.

Take the Next Step: Ready to tackle sheet formation challenges? Whether you’re a paper maker seeking process improvements or a fabric manufacturer innovating designs, PMC Centre is here to support you with data-driven, mill-specific solutions.

📖 Dive deeper: Explore detailed strategies and case studies on our blog: [www.pmccentre.com/blog](#).

💬 Join the conversation: What formation hurdles are you facing, and how are you addressing them? Share your insights below—we’d love to connect!

Comments