top of page

Search

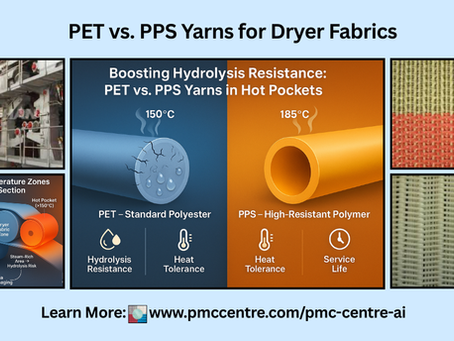

PET vs. PPS Yarns for Dryer Fabrics

In demanding dryer sections, hydrolysis weakens yarn integrity under high heat and humidity, shortening fabric life and raising costs. Hot pockets (>150°C) intensify this risk, requiring materials that balance durability with performance. This article compares PET vs. PPS yarns and key monitoring practices to limit thermal breakdown. 1. PET Yarns: Enhancing Standard Durability: Polyester (PET) yarns offer cost-effective permeability for most dryer applications but degrade

Snehes Dasgupta

Jan 32 min read

Mastering Sheet Formation: A Collaborative Guide for Paper Makers and Forming Fabric Manufacturers

Poor sheet formation —characterized by uneven fiber distribution, mottling, and inconsistent quality—poses a significant challenge in paper production, impacting strength, printability, and operational efficiency. At PMC Centre , we bridge the gap between paper makers and forming fabric manufacturers, combining expert insights to address this pain point holistically. By understanding the interplay of pulp properties, machine configurations, and fabric design, both sides can c

Snehes Dasgupta

Sep 18, 20254 min read

bottom of page