Latest Advances in High-Support Forming Fabrics

- Snehes Dasgupta

- Jan 17

- 5 min read

In the high-stakes world of modern papermaking, where machines run at blistering speeds and every percentage point in efficiency counts, the wet end remains the battleground for optimizing drainage, retention, and sheet quality. As production demands escalate—coupled with relentless pressure to slash energy costs and minimize environmental impact—forming fabrics must evolve beyond traditional designs. A landmark study from Albany International, presented at PaperCon 2011, spotlights two game-changing innovations in Sheet Supporting Binder (SSB) triple-layer forming fabrics: a high-support structure with a 3:1 cross-machine direction (CD) yarn ratio and a proprietary surface enhancement process. These advancements, validated through rigorous lab tests and real-world trials, promise 15-35% gains in fiber support index (FSI), reduced fabric caliper, and cleaner operations—translating to fewer breaks, higher solids, and superior print quality.

At PMC Centre, we champion unbiased, data-driven insights into Paper Machine Clothing (PMC) challenges. This blog dives deep into these concepts, drawing directly from the research to equip paper makers and fabric manufacturers with actionable knowledge. Whether you're troubleshooting formation issues or selecting fabrics for high-speed gap formers, understanding these structural tweaks can unlock measurable ROI. Let's explore how they're reshaping the wet end.

The Evolving Demands on Forming Fabrics: Drainage Meets Retention

Forming fabrics are the unsung heroes of the wet end, tasked with two core imperatives: efficient drainage through their weave and robust retention of fibers on the surface. Traditional performance metrics—mechanical stability, permeability, and FSI—have long been tied to weave patterns and monofilament materials. But today's complexities demand more: speeds exceeding 1800 m/min, energy audits under scrutiny, and grades like supercalendered (SC) magazine paper requiring pinpoint formation and smoothness.

SSB triple-layer designs dominate publication-grade machines for their balanced dewatering behavior. Yet, as the paper notes, papermaking's shift toward structural optimization and material finesse has birthed these enhancements. By boosting paper-side CD yarns and refining yarn diameters, designers achieve finer meshes without sacrificing air permeability. The result? Smoother surfaces that cradle fibers like a uniform membrane, minimizing defects and maximizing fines/filler retention.

Concept 1: High-Support Structures – Elevating Fiber Support Index (FSI):

The first innovation reimagines the CD yarn ratio in SSB fabrics, jumping from the conventional 2:1 (paper-side to wear-side) to 3:1. This simple ratio shift packs more CD yarns topside, inflating support points and FSI by 15-35% while trimming wear-side density for openness.

Consider the comparative data from the study (Table I below, adapted for clarity):

Fabric ID | Paper-Side Mesh (MD x CD /cm) | Yarn Diameters (MD:CD [mm]) | Support Points (No/cm²) | FSI | Caliper (mm) | Air Perm (CFM) | CD Ratio (Top:Bottom) | |

FA (2:1) | 28.5 x 39.0 | 0.13/0.21 : 0.13/0.30 | 1,130 | 180 | 0.89 | 350 | 2:1 | |

FB (2:1) | 34.5 x 42.0 | 0.11/0.18 : 0.11/0.25 | 1,450 | 200 | 0.72 | 350 | 2:1 | |

FC (2:1) | 38.0 x 43.0 | 0.10/0.17 : 0.10/0.24 | 1,635 | 210 | 0.68 | 350 | 2:1 | |

FD (3:1) | 28.5 x 47.0 | 0.13/0.21 : 0.13/0.30 | 1,340 | 207 | 0.85 | 350 | 3:1 | |

FE (3:1) | 34.5 x 58.0 | 0.11/0.18 : 0.11/0.25 | 2,000 | 255 | 0.71 | 340 | 3:1 | |

FF (3:1) | 38.0 x 58.0 | 0.10/0.17 : 0.10/0.25 | 2,200 | 261 | 0.71 | 355 | 3:1 |

Fabrics FA-FC represent proven 2:1 baselines for woodfree, newsprint/LWC, and rotogravure SC grades. Their 3:1 counterparts (D-F) mirror MD specs but surge CD counts—e.g., Fabric FE's 58/cm vs. B's 42/cm—yielding 38% more support points. Caliper holds steady (or dips slightly), and permeability remains consistent, ensuring no drainage trade-offs.

Micro X-ray computed tomography reveals why: 3:1 fabrics form a thin, uniform "membrane" topside (30-35% open area in the ~0.1 mm top layer) atop a rigid, open understructure. This bottlenecks flow minimally while enhancing sheet uniformity. Lab trials confirmed faster drainage and 10-15% better PCC retention for eucalyptus pulp (80 g/m², SR°30). On-machine, the denser contact points reduce plane differences between MD/CD knuckles, curbing contaminant adhesion and easing sheet release—keeping return runs pristine and breaks at bay.

In essence: Higher FSI isn't just numbers; it's a shield against porosity spikes, roughness, and lost production. For gap formers, where low caliper is king, Fabric FC/FF hybrids are game-changers.

Concept 2: Surface Enhancement – Flattening for Efficiency and Cleanliness:

The second pillar? A heated compaction process that flattens paper-side knuckles, densifies the weave, and shrinks caliper/void volume by 5-15%. Applied to a baseline SSB like Fabric B, it yields:

Surface Enhancement | Open Area at Surface (%) | Caliper (mm) | Void Volume | Air Perm (CFM) | Plane Difference (µm) |

Non-Enhanced | 39 | 0.70 | 0.57 | 350 | 30 |

Enhanced | 37 | 0.65 | 0.55 | 350 | 20 |

CD yarn density tweaks maintain permeability and surface openness. SEM and tomography visuals show flattened knuckles and a compacted cross-section, shifting the "bottleneck" layer upward and slashing the mid-fabric void (at ~0.22 mm depth) that traps water and causes rewetting.

Benefits cascade: Smoother topography minimizes fiber embedding, boosts vacuum efficiency for 0.5-1% higher couch solids, and starves contaminants of hiding spots. Worn fabrics see similar uplifts, extending life. As prior research affirms, thinner calipers cut dryer steam by correlating to uniform drying—critical at speeds where non-uniformity amplifies losses.

Case Studies from High-Speed Machines:

Theory shines in practice. Three trials on publication-grade formers underscore the dual concepts' synergy:

Case 1: M/C Speed 1800 mpm:

Swapping to finer 2:1 Fabric FC slashed porosity and PPS roughness. But cleanliness lingered—until high-support 3:1 Fabric FE hit the outer position (with FB inner). Wet-end breaks plunged >50% (9% to <4.5% lost production), gloss rose to 55.3%, and missing dots halved. Now standard.

Fabric | Gloss (TS) | PPS (TS) | Missing Dots (dots/unit area) | Sheet Breaks (% Lost Production) |

FB | 53.1 | 1.1 | 1.7 | 9.0 |

FE | 55.3 | 1.0 | 1.0 | 4.5 |

Case 2:M/C Speed 1250 mpm:

High-support FD/FE fabrics (top enhanced) tackled drainage limits. Couch solids +0.8%, press solids +1.0% (Fig. 11)—outpacing the typical 0.25% carryover, thanks to better formation. Steam dropped 4.1%, speeds rose 15-45 mpm, and breaks fell from 2.0 to 1.4/day. Cleaner former = fewer defects.

Case 3: M/C Speed 1650 mpm

Starting with FB (2:1), trials progressed: FE (3:1) improved porosity but misted; enhanced FE curbed profiles; FF (3:1, enhanced) on both positions locked in low porosity/roughness with tight 2-sigma basis weight variance. Uniformity now rules, sans water mist.

These aren't outliers— they're scalable wins for energy-hungry, break-prone wet ends.

Charting the Gains: Visualizing Key Metrics

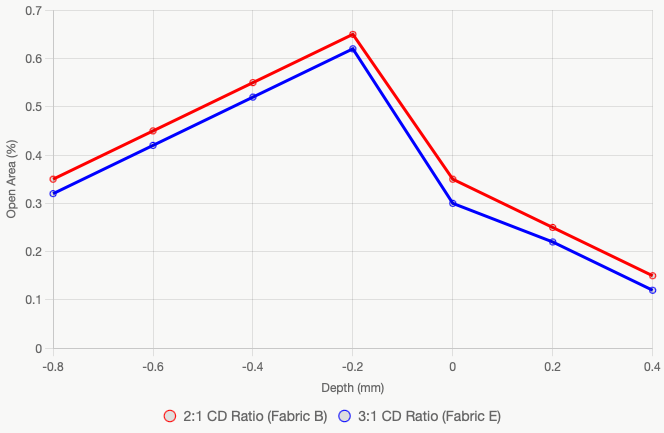

To illustrate the structural edge, here's a simplified line chart of open area vs. depth for 2:1 (red) vs. 3:1 (blue) fabrics, based on tomography data. Note the finer top "membrane" and persistent openness below.

This "funnel" effect—tight topside, expansive core—explains the dewatering prowess.

Looking Ahead: Implementing These in Your Operation-

As machines grow faster and greener, high-support and enhanced fabrics aren't luxuries—they're essentials for retention, solids, and uptime. Root causes like uneven FSI lead to porosity woes; solutions like 3:1 ratios and compaction address them head-on. At PMC Centre, our consultancy dissects your wet-end data to match these to your grade and former—no vendor bias.

Ready to troubleshoot? PMC Centre AI—powered by advanced models—delivers 24/7 diagnostics for forming fabrics. Upload specs or symptoms for instant, expert guidance.

🔗 Explore more on forming fabric optimization: [www.pmccentre.com/blog](https://www.pmccentre.com/blog)

🚀 Try PMC Centre AI free:www.pmccentre.com/pmc-centre-ai

What wet-end challenge are you tackling next? Share in the comments—we're here to collaborate.

Comments