top of page

Search

Latest Advances in High-Support Forming Fabrics

In the high-stakes world of modern papermaking, where machines run at blistering speeds and every percentage point in efficiency counts, the wet end remains the battleground for optimizing drainage, retention, and sheet quality. As production demands escalate—coupled with relentless pressure to slash energy costs and minimize environmental impact—forming fabrics must evolve beyond traditional designs. A landmark study from Albany International, presented at PaperCon 2011, spo

Snehes Dasgupta

Jan 175 min read

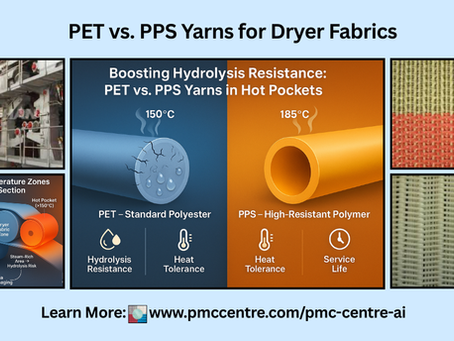

PET vs. PPS Yarns for Dryer Fabrics

In demanding dryer sections, hydrolysis weakens yarn integrity under high heat and humidity, shortening fabric life and raising costs. Hot pockets (>150°C) intensify this risk, requiring materials that balance durability with performance. This article compares PET vs. PPS yarns and key monitoring practices to limit thermal breakdown. 1. PET Yarns: Enhancing Standard Durability: Polyester (PET) yarns offer cost-effective permeability for most dryer applications but degrade

Snehes Dasgupta

Jan 32 min read

Woven vs. Spiral Dryer Fabrics: Where to Use Which, and Why

In the high-stakes dryer sections of paper machines, selecting and positioning the right fabric—woven or spiral—can significantly enhance drying efficiency, sheet quality, and operational uptime. Woven fabrics excel in controlled contact and surface finish, while spirals prioritize permeability and durability in demanding conditions. This comprehensive guide combines insights from our recent LinkedIn series to help technical teams optimize placements, drawing on proven applic

Snehes Dasgupta

Nov 24, 20253 min read

Tackling Guiding and Alignment Challenges in Forming Fabrics: A Guide for Paper Makers and Manufacturers

In the fast-paced world of paper production, few issues are as disruptive as forming fabric wandering—where imbalances in tension,...

Snehes Dasgupta

Oct 1, 20254 min read

Tackling Uneven Wear in Forming Fabrics: A Guide for Paper Makers and Manufacturers

In the high-stakes world of paper production, uneven wear on Forming Fabrics can spell trouble—from compromised sheet quality to unexpected downtime. At PMC Centre, we specialise in Paper Machine Clothing (PMC) solutions that bridge the gap between paper mills and fabric manufacturers. This blog dives deep into the causes, impacts, and practical fixes for uneven wear, drawing from real-world challenges faced by both Paper Makers and Forming Fabric Manufacturers. Whether you'r

Snehes Dasgupta

Sep 15, 20254 min read

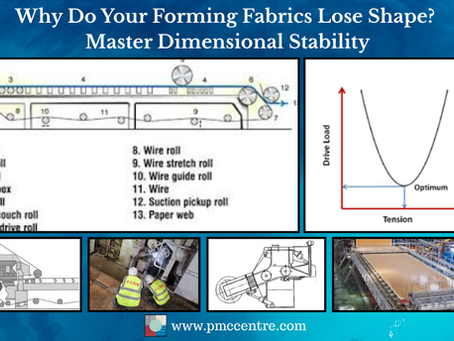

Why Does Your Forming Fabric Lose Shape Too Soon? Mastering Dimensional Stability

Why Does Your Forming Fabric Lose Shape? Mastering Dimensional Stability

Poor dimensional stability in forming fabrics—lengthwise elongation or widthwise shrinkage—causes sheet defects, downtime, and higher costs. This blog explores how paper makers and manufacturers can address this critical issue.

Snehes Dasgupta

Sep 2, 20255 min read

bottom of page