Tackling Guiding and Alignment Challenges in Forming Fabrics: A Guide for Paper Makers and Manufacturers

- Snehes Dasgupta

- Oct 1, 2025

- 4 min read

In the fast-paced world of paper production, few issues are as disruptive as forming fabric wandering—where imbalances in tension, friction, or alignment lead to downtime, uneven sheet formation, and reduced efficiency. Whether you're a paper maker troubleshooting on the mill floor or a fabric manufacturer striving to deliver flawless products, understanding and addressing these challenges is key to optimizing performance.This blog draws from our recent social media series, combining insights for both sides of the equation. Let's dive in.

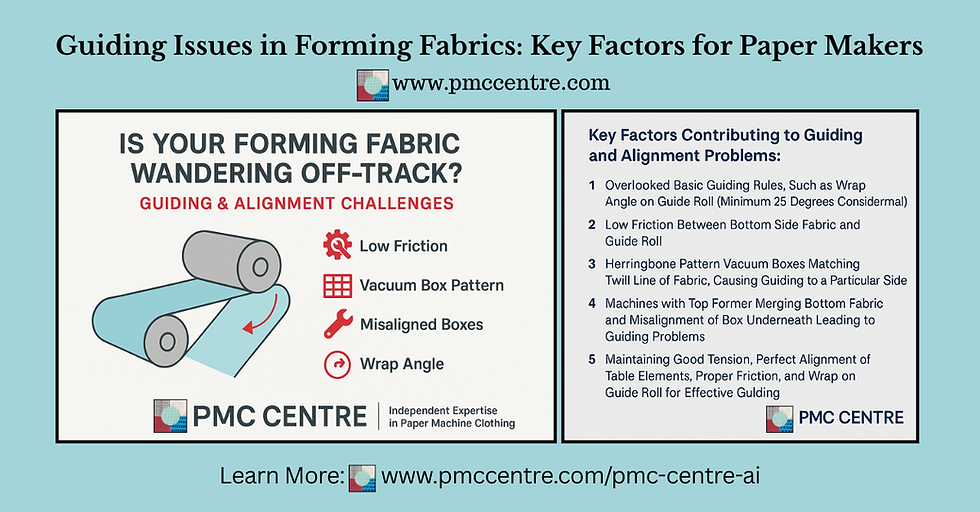

For Paper Makers: Identifying and Resolving Guiding Issues on the Machine:

Paper makers, we've all faced the frustration of a forming fabric drifting—leading to unplanned downtime and inconsistent sheet formation that disrupts your entire run. Addressing these issues promptly can boost efficiency and quality.

Here's a breakdown of key contributing factors:

Overlooked Basic Guiding Rules, Such as Wrap Angle on Guide Roll (Minimum 25 Degrees Considered Normal): Basic rules are indeed frequently overlooked, leading to preventable issues. The wrap angle—the degree of fabric contact around the guide roll—directly influences guiding effectiveness by enhancing friction and control.

Low Friction Between Bottom Side Fabric and Guide Roll: Low friction is a key factor in guiding failures, as it prevents the fabric from responding to directional corrections. The bottom side's topography—referring to the surface texture from weave patterns or yarn materials—can reduce contact grip (more details in the manufacturers' section below).

Herringbone Pattern Vacuum Boxes Matching Twill Line of Fabric, Causing Guiding to a Particular Side: This is a specific but verified issue where pattern alignment creates directional bias under vacuum. Switch to slotted covers for better dewatering and less wear; alternate drill angles in boxes, with the final one opposite the fabric's twill, to balance twill patterns.

Machines with Top Former Merging Bottom Fabric and Misalignment of Box Underneath Leading to Guiding Problems: In twin-wire or top former machines, where top and bottom fabrics merge, misalignment of underlying elements like vacuum boxes can disrupt guiding. Use precision tools for alignment; check during installations; this is especially critical in shorter fabrics like top formers, where setup issues amplify problems.

Maintaining Good Tension, Perfect Alignment of Table Elements, Proper Friction for Effective Guiding: This holistic approach is strongly supported, as these elements interconnect to ensure stable fabric tracking. Regular checks with tools like tension meters; grind roll covers periodically; optimize showers for water control.

By tackling these factors head-on, you can minimize disruptions and maintain consistent production.

For Fabric Manufacturers: Precautions to Deliver Stable, High-Performance Fabrics:

Fabric manufacturers, building on the paper machine factors like tension and friction imbalances discussed above, your role is pivotal in preventing these issues from the start.

Here's how you can deliver perfectly square, stable fabrics that keep paper makers' operations on track:

Length Variation Control: Before dispatch, measure fabric length variation on each side. Keep it tight—within 10-20 mm total, or 1 mm/m for fabrics under 25 m—to ensure uniform tension and prevent fabric guiding issues.

Optimized Weave Pattern: As highlighted in the paper makers' section, herringbone suction box patterns can influence tracking. Opt for a broken twill weave on the fabric machine side instead of straight twill to enhance stability and reduce drift. This weave minimizes lateral stress, ensuring the fabric resists skewing under dynamic loads.

Precision in Manufacturing Process: Achieving a square fabric with minimal length/width variation and robust modulus starts with raw material selection (Polyester/Polyamide) and extends to precise warping, weaving, and heat-setting parameters. Consistency here is non-negotiable. For some paper machines with chronic guiding issues, machine-side grinding of the fabric can significantly improve tracking performance.

Machine Settings Maintenance: Regularly calibrate warping, weaving, and heat-setting machines. Ensure finishing rollers are equidistant and corrected to maintain fabric squareness and eliminate alignment issues downstream. Scheduled maintenance logs and real-time monitoring systems help detect and correct deviations before they impact fabric quality.

Tailored Supply Length: Match fabric length to the paper machine’s min/max loop length and operating tension. This ensures uniform tension, prevents slippage, and minimizes guiding challenges. Collaborating with paper makers to understand their specific machine configurations allows for precise length customization, enhancing performance.

Impacts of These Measures: Implementing these steps cuts down on customer complaints, extends fabric life, and boosts mill efficiency by avoiding downtime—ultimately enhancing your reputation and reducing rework costs.

Partnering for Success with PMC Centre

At PMC Centre, our independent consultancy delivers unbiased, results-driven expertise to diagnose and resolve these issues for paper makers and manufacturers alike.

No fabric sales—just focused optimization to elevate your operations. Ready to align your processes? Visit www.pmccentre.com or connect with us today.

For deeper technical insights, explore our blog at www.pmccentre.com/blog.

Bonus Tip: Test-drive PMC CENTRE AI, our free beta AI assistant dedicated to Paper Machine Clothing. Troubleshoot fabric specs, optimize production, and get instant insights at www.pmccentre.com/pmc-centre-ai.

Join global users already registering!Let's collaborate to keep fabrics running true. What's your biggest challenge in guiding and alignment? Share your thoughts in the comments.

Comments