top of page

Search

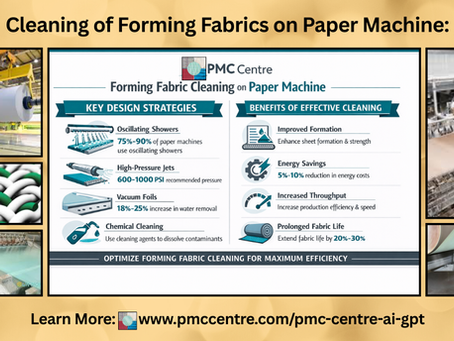

Guide for Cleaning and Conditioning Forming Fabrics for Paper Machines

Maintaining the cleanliness and conditioning of forming fabrics is one of the most critical yet often misunderstood aspects of maximizing runnability and paper quality in modern paper machines. In the high-speed and high-contaminant environment of today’s furnish — particularly with the increased use of recycled fibers — forming fabric performance directly influences drainage efficiency, sheet formation, fiber retention, runnability, and ultimately the economic performance of

Snehes Dasgupta

Jan 3010 min read

A Practical Guide to Forming Fabric Design for Retention

In the fast-paced world of high-speed paper production, retention isn't just a metric—it's a cornerstone of efficiency. Poor retention results in lost fillers and fines, escalating chemical costs, inconsistent sheet quality, and ultimately, reduced mill profitability. For fabric manufacturers, the challenge lies in designing forming fabrics that enhance retention while maintaining optimal drainage and formation. This guide delves into the critical design elements—caliper, voi

Snehes Dasgupta

Jan 104 min read

Navigating Dryer Fabric Challenges: Key Pain Points and Solutions for Woven and Spiral Designs in Paper Machines

In today's high-speed paper machines processing high-fines and recycled furnishes, the dryer section remains a critical bottleneck for efficiency and profitability. Woven and spiral dryer fabrics each offer unique advantages—such as stability and permeability—but mismatching them to machine positions, heat loads, or contaminants can lead to sheet defects, elevated energy use, and frequent downtime. Drawing from recent industry insights, this post outlines the top pain points

Snehes Dasgupta

Dec 5, 20253 min read

Tackling Guiding and Alignment Challenges in Forming Fabrics: A Guide for Paper Makers and Manufacturers

In the fast-paced world of paper production, few issues are as disruptive as forming fabric wandering—where imbalances in tension,...

Snehes Dasgupta

Oct 1, 20254 min read

Tackling Uneven Wear in Forming Fabrics: A Guide for Paper Makers and Manufacturers

In the high-stakes world of paper production, uneven wear on Forming Fabrics can spell trouble—from compromised sheet quality to unexpected downtime. At PMC Centre, we specialise in Paper Machine Clothing (PMC) solutions that bridge the gap between paper mills and fabric manufacturers. This blog dives deep into the causes, impacts, and practical fixes for uneven wear, drawing from real-world challenges faced by both Paper Makers and Forming Fabric Manufacturers. Whether you'r

Snehes Dasgupta

Sep 15, 20254 min read

bottom of page