top of page

Search

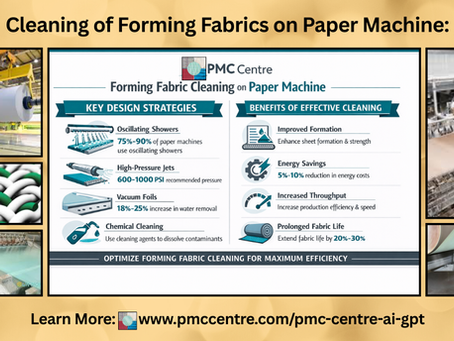

Guide for Cleaning and Conditioning Forming Fabrics for Paper Machines

Maintaining the cleanliness and conditioning of forming fabrics is one of the most critical yet often misunderstood aspects of maximizing runnability and paper quality in modern paper machines. In the high-speed and high-contaminant environment of today’s furnish — particularly with the increased use of recycled fibers — forming fabric performance directly influences drainage efficiency, sheet formation, fiber retention, runnability, and ultimately the economic performance of

Snehes Dasgupta

Jan 3010 min read

Latest Advances in High-Support Forming Fabrics

In the high-stakes world of modern papermaking, where machines run at blistering speeds and every percentage point in efficiency counts, the wet end remains the battleground for optimizing drainage, retention, and sheet quality. As production demands escalate—coupled with relentless pressure to slash energy costs and minimize environmental impact—forming fabrics must evolve beyond traditional designs. A landmark study from Albany International, presented at PaperCon 2011, spo

Snehes Dasgupta

Jan 175 min read

A Practical Guide to Forming Fabric Design for Retention

In the fast-paced world of high-speed paper production, retention isn't just a metric—it's a cornerstone of efficiency. Poor retention results in lost fillers and fines, escalating chemical costs, inconsistent sheet quality, and ultimately, reduced mill profitability. For fabric manufacturers, the challenge lies in designing forming fabrics that enhance retention while maintaining optimal drainage and formation. This guide delves into the critical design elements—caliper, voi

Snehes Dasgupta

Jan 104 min read

bottom of page