How to Effectively Manage Wire Marking Issues to Enhance Your Paper Quality

- Snehes Dasgupta

- Aug 3, 2025

- 3 min read

Updated: Aug 5, 2025

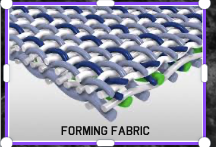

Wire marking can be a major setback in paper production, impacting the overall quality of sheets and leading to increased rejects and costs. As paper makers, it’s crucial to take proactive steps to combat these unwanted impressions caused by the forming fabric. By understanding the underlying causes of wire marking and implementing targeted solutions, you can maintain a high standard in your paper products. Let’s delve into how you can take control of this issue and enhance your production quality.

Uneven Wire Surface or Wear

One of the primary causes of wire marking is an uneven surface or wear on the wire weave. When your forming fabric is worn or inconsistent, it can transfer unwanted patterns onto the paper sheets. Regular inspections using wear profile analysis are essential to detect wear at an early stage.

By replacing worn wires promptly, you can maintain a smooth, consistent surface, allowing for optimal sheet formation without markings.

Residue Buildup on Wire

Sticky pulp or other contaminants can lead to localized marks on the finished paper. Over time, residue can accumulate on the wire, making it essential to keep your forming fabric clean.

Consider upgrading to high-pressure micro-travel showers or advanced cleaning systems that effectively remove debris and contaminants. A clean wire contributes significantly to higher quality paper production and minimizes the risk of wire marking.

Inconsistent Pulp Properties

The quality of the pulp being processed plays a vital role in how wire marking is manifested. Abrasive or inconsistent pulp properties can worsen marking and create an undesirable appearance on the final product.

To combat this issue, closely monitor and adjust your pulp properties. Ensuring consistency in pulp quality helps minimize abrasive effects, improving both production efficiency and product quality.

Localised Wear from Misalignment

Misalignment of the machine components can lead to localized areas of wear that produce impressions on the paper.

Conducting routine machine audits is essential to ensure all elements are properly aligned and that the surfaces of moving and stationary parts—like rolls or suction boxes—are maintained effectively. A well-aligned machine minimizes localized wear and helps achieve a higher quality of paper.

Very High Vacuum Levels

While vacuum settings are crucial for effective dewatering, excessively high levels can exacerbate wire marking by increasing pressure on the sheet.

It is important to optimize vacuum settings to strike a balance between efficiency and the risk of marking. Adjusting the vacuum levels can help mitigate the pressure placed on the sheet and preserve the quality of your final product.

Worn or Poorly Designed Wire Seams

The seams of the forming fabric are another area that can contribute to wire marking if they are worn or poorly designed.

Developing a partnership with wire suppliers can help you select seams that are tough and low-profile, tailored specifically for your machine. Investing in high-quality seams will reduce the risk of markings and ultimately enhance your paper quality.

Conclusion

Wire marking is an issue faced by many paper makers, but it doesn't have to be an insurmountable challenge. By actively addressing the various factors that contribute to wire marking, such as uneven wire surfaces, residue buildup, pulp properties, and machine alignment, you can significantly improve the quality of your paper products.

Moreover, collaborating with wire suppliers to ensure the best seams are in use can make a substantial difference. It is through these proactive measures that you can combat wire marking and maintain a high standard in your production processes.

Have tips or experiences with wire marking? Share them in the comments below—we’d love to hear your insights! Take control of wire marking today by visiting www.pmccentre.com for expert resources to optimize your processes and enhance paper quality.

Comments