Seam Failure in Forming Fabrics: Expert Tips for Paper Makers and Forming Fabric Manufacturers

- Snehes Dasgupta

- Sep 27, 2025

- 4 min read

Seam failure in forming fabrics can cause significant disruptions in paper mills, leading to costly downtime and decreased productivity. This blog post will delve into the reasons seam failure occurs and provide actionable insights for both paper makers and forming fabric manufacturers.

Understanding the Impact of Seam Failure for Paper Makers

Seam failure is a critical issue that can create major problems in a paper production environment. A broken seam can halt a production line, resulting in unplanned downtime that may cost a mill thousands of dollars per hour. Understanding the causes and implications of seam failure helps paper makers protect their processes and profitability.

Causes of Seam Failure

Several factors can contribute to seam failure in forming fabrics, including:

Improper machine conditions: Inconsistent machine settings or malfunctioning parts can contribute to the degradation of seams.

Lack of proper alignment: Misalignment can lead to increased stress on seams, resulting in failure.

Natural wear and tear: Continuous operation can subject seams to wear, increasing the likelihood of failure.

Actions to Mitigate Risks of Seam Failure

To help minimize the risks associated with seam failure, paper makers can employ the following strategies:

Regular Inspection of Machinery

Inspect machine conditions routinely to identify potential issues before they cause seam failures.

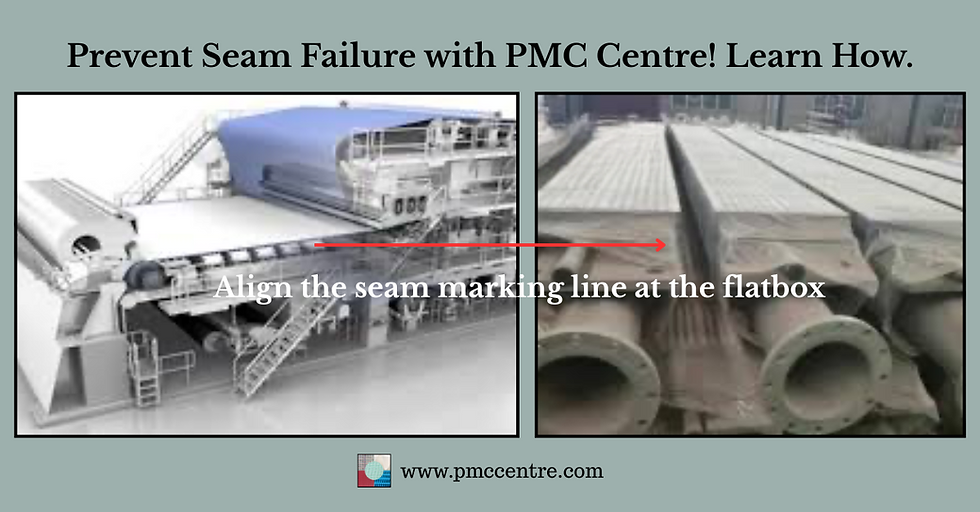

Ensure Proper Seam Alignment

Verify that seams are properly aligned during the installation of forming fabrics. Regular checks can prevent misalignments that lead to stress.

Monitor Seam Wear

During shutdowns, take time to check the seams for wear patterns or signs of degradation. This proactive approach can help you plan fabric replacements before a failure occurs.

Prevent Wear Failures: Excessive body wear often leads to seam failure. Monitor fabric caliper regularly and stay within manufacturers safe limits. Regular checks can provide early warning signals before seams fail, saving manufacturers and their clients from costly issues.

By implementing these strategies, paper makers can reduce seam failure risks, leading to a more efficient operation.

The Cost of Downtime and Importance of Monitoring

Understanding the cost of downtime caused by seam failure is crucial for optimizing operations. A study found that unplanned downtime can account for up to 40% of a paper mill's total manufacturing cost. This emphasizes the need for paper makers to adopt preventative measures.

Engaging with Other Paper Makers

If you are facing challenges related to seam failure or want to share your experiences, we encourage you to connect with other professionals in the field. Follow PMC CENTRE for more insights and updates in the paper making industry.

Tips for Forming Fabric Manufacturers

Forming fabric manufacturers play a pivotal role in addressing seam failure complaints from their clients. By focusing on high-quality production techniques, manufacturers can greatly minimize return rates and enhance customer satisfaction.

Addressing Customer Complaints

When customers report seam failures, it's essential to respond effectively. Manufacturers should take the following steps:

Investigate Weaving Techniques

Examine the weaving process to ensure it meets industry standards. Proper weaving techniques can enhance seam strength.

Proper Heat Setting

Ensure that fabrics undergo appropriate heat setting to increase seam durability. This critical step can significantly prevent seam failures during operation.

Monitor Seam Strength

Regularly test seam strength in different fabric batches to identify any fluctuations in quality that could indicate potential issues.

Balancing Body and Seam Properties

Focus on creating a balance between the body of the fabric and its seams. This might require testing various materials to find an optimal combination.

Preventing Wear Failures

Develop strains and tests to simulate wear on seams, allowing for improvements before a fabric is rolled out for production.

Collaborating with Customers

Don't view your customers' complaints merely as issues to resolve. Use them as opportunities for collaboration. Discussing challenges openly can lead to breakthroughs in product improvements.

If you are a forming fabric manufacturer experiencing challenges with seam failures, reach out to colleagues in the industry for brainstorming sessions or seek guidance from experts. Follow PMC CENTRE for continual learning and support.

Strengthening Relationships in the Industry

To foster a culture of knowledge sharing and collaboration, both paper makers and forming fabric manufacturers should cultivate relationships within the industry. Engaging in dialogue and sharing experiences can lead to better understanding and solutions to seam failure problems.

Encourage discussions and seminars that involve both sectors. When both paper makers and fabric manufacturers share insights, it's easier to identify patterns and develop better technologies and practices.

Continuous Adaptation and Learning

The landscape of paper manufacturing is continuously evolving, as technological advancements emerge. As new practices develop, it is essential for both paper makers and forming fabric manufacturers to stay updated.

Participate in workshops and conventions to understand the latest methodologies around seam strength and fabric quality. Sharing findings and innovations can drive industry standards upwards.

By embracing continuous learning and adaptation, your team will be better equipped to overcome challenges related to seam failure.

Final Thoughts

Seam failure can be an unwelcome challenge for both paper makers and forming fabric manufacturers. By implementing best practices for monitoring and maintenance, proactive steps can significantly reduce the risk of failures. Engaging with the community through discussions and shared experiences can foster better solutions and broader knowledge bases.

Stay connected for further insights by following PMC CENTRE on LinkedIn or visiting the website for more expert insights into the paper making and fabric manufacturing industries. Sharing your challenges and solutions will benefit not only your operations but the industry as a whole.

Comments